Difference Between PCD Pharma & Third Party Manufacturing

April 18, 2024

Table of Contents

In India, the pharmaceuticals industry has advanced greatly and those who have marched with the pace of it have made profits. As the industry is very bright, launching a pharma business is still profitable. It doesn’t matter that you compete with the PCD Pharma Distributors or establish a manufacturing unit, the success is guaranteed. But sometimes people just can’t differentiate between the various business models within this industry. If you are also confused between PCD Pharma and Third Party Manufacturing, then this article is just right for you.

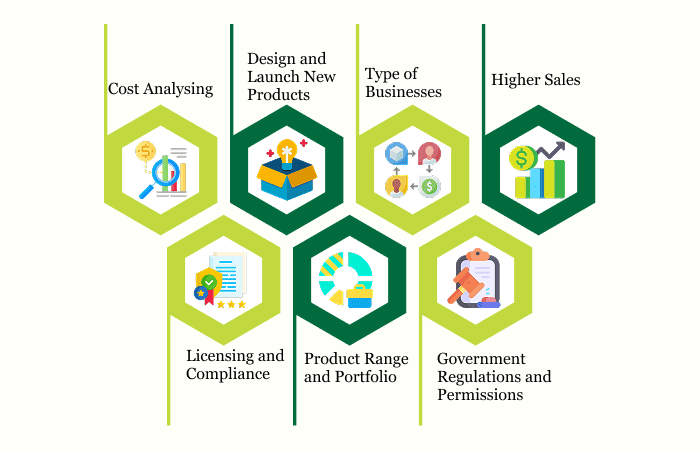

Major Difference Between PCD Pharma & Third Party Manufacturing

While both business models involve cooperation between pharmaceutical companies, PCD Pharma Franchise is different as it goes beyond manufacturing. It encircles distribution, sales and marketing making it an amazing option for entrepreneurs looking to start their career in the pharmaceutical sector. Whereas, in third-party manufacturing, companies outsource the production of medications to external manufacturers. Both business models operate on different principles and cater to different purposes. Here are a few more differences between PCD Pharma & Third Party Manufacturing:

Cost Analysing:

It is important to conduct an in-depth cost analysis between the two business models. Usually, the third-party manufacturing demand low expenses in the initial stages as companies mainly focus on outsourcing production to dedicated manufacturers while bringing down the requirement of operational and infrastructure costs. On the contrary, higher expenses will be incurred by PCD Pharma because of the creation of marketing campaigns, distribution networks and franchisee training.

Licensing and Compliance:

In the case of PCD Pharma, they do not need to have their license as the parent company has all the necessary licenses. Whereas in the case of Third Party Manufacturing, the client needs to have their manufacturing licenses. This makes PCD Pharma a more accessible option for small businesses and entrepreneurs.

Design and Launch New Products:

When it comes to designing and launching new products, PCD Pharma has limited control. The parent company does all the research, development and testing of the new product, the PCD Pharma has to just distribute it. On the other hand, companies using Third Party Manufacturing have more flexibility. Here the manufacturer comes up with the new idea, or the company might work closely with the manufacturer to fine-tune the idea of the new product.

Product Range and Portfolio:

PCD Pharma companies have a limited product range, backed by only the products offered by the parent company. This limitation can be a drawback for entrepreneurs who wish to scale their business by offering a wide range of pharma products. Whereas, companies that work with Third Party Manufacturing have the choice to increase their product portfolio as per the demands of the market.

Type of Businesses:

PCD Pharma is great for small to mid-sized businesses or entrepreneurs, who want to enter into the pharma industry without the stress of manufacturing. On the other hand, the business model of Third Party Manufacturing suits companies that already have a strong presence in the market and want to increase their product range without establishing their manufacturing unit.

Government Regulations and Permissions:

Both business models necessitate government permissions and regulations. In the case of PCD Pharma, the parent company takes care of most of the government permissions. The PCD Pharma just have to concentrate on marketing authorisation and distribution licences. On the contrary, the company outsourcing the production must ensure that all the government permissions are taken before the manufacturing begins. This includes regulations related to drug manufacturing and quality control.

Higher Sales:

In PCD Pharma, higher scales could be achieved because of access to a wide range of established products. Additionally, the benefit of the parent company’s brand recognition also comes in handy. Whereas, in Third Party Manufacturing the sales rely more on the marketing efforts by the client and the quality of the product.

PCD Pharma and Third Party Manufacturing are both great ways to get into the pharma business, but they serve different needs and business goals. PCD Pharma is a good option for businesses that want to establish their brands and take advantage of local market understanding. While Third Party Manufacturing provides cost-efficiency and product scalability. Pharmaceutical entrepreneurs can drive growth and success in the competitive pharma sector by taking the time to consider which business model fits their goals.

At Albia Biocare, we understand that every business has unique needs. That is why we help with flexible solutions that serve the needs of both PCD Pharma partners and those interested in Third Party Manufacturing. As one of the leading pharma companies in Chandigarh, we are dedicated to helping you understand these business models. Whether you are looking to be our PCD Pharma distributors or exploring Third Party Manufacturing, Albia Biocare is here to support you with our large product portfolio and expertise. Partner with us and take the next step in your pharma journey.

Leave a Reply